“Basic learning of cellulose nanofibers”

Minor change in Section 2 by Nogi 2020/11/26

Add the Experimental section by Nogi 2020/10/15

text by Nogi 2020/08/30

英語が得意じゃない学生さんへ

DeepL翻訳、Google translateなどウェブ翻訳サービスを最大限に活用して、下記の文章を理解してください。そして、解答は日本語で構いません。模範解答は英語で送りますけど、悪しからず。

Contents

Introduction. History will repeat itself.

Review. Wood cell walls & Cellulose microfibrils?

Section 1. Basic Five terms: “cellulose”, “cellulose fiber”, “pulp fiber”, “wood cells”, and “cellulose microfibril”

Section 2. Figure out the size gap

Intermission 1. What is “Nanocellulose”?

Section 3. Paper history: why the wood cellulose is important?

Section 4. How to produce the paper in the factory

Section 5. History of tracing paper

Intermission 2. The easiest way to get cellulose nanofibers

Section 6. How to make the cellulose nanofiber & nanopaper

Intermission 3. Bottom up approach to the cellulose nanofibers

Overview

Introduction. History will repeat itself.

You must understand the cellulose microfibrills and cell wall structures, before starting this page.

If not, please access “Learn the wood structure“

Here we will basically explain about the cellulose nanofibers & its production processes. To get their basic knowledge, you should understand the following three topics.

1. learn the technical terms at a high school or under graduate level.(section 1)

2. learn/feel/figure out the size of cellulose micro fibrills, cell wall, and wood blocks. (section 2)

3. learn the R&D history in paper and cellulose. (section 3-5)

All the present technology are linked or created by past ones. Therefore, you can understand the latest ones, when you understand the previous ones.

4. Basic learning of cellulose nanofibers & their productions. (section 6)

History will repeat itself. Therefore, when you understand the size & history, you will get the basic knowledge. If you don’t understand the size & history, you will never.

Review: wood cell walls & cellulose microfibrils

Answer the questions, reading the below URL.

http://www.nogimasaya.com/favorite/learn-the-wood-structures/

Q.O-0 Answer the hierarchical wood structure in (a)-(h).

Q.6-3 Answer the three principle chemical composition in wood.

Q.6-6 How to combine the cell walls?

Q.9-2 Answer the four layers in the cell wall.

Q.9-5 Answer the orientation in the four layers.

Q.9-8 Answer the reason the cellulose microfbril or MFA is the king of the wood.

Q.10-1 Answer where the cellulose microfibrils are born in the macro & microscopic, respectively.

Q.10-2 What’s happened after producing?.

Q.10-10 How much width are the cellulose microfibrils just after produced?

Q.10-4 Answer the width in the cellulose microfibril bundles when we observe the cell walls using the FE-SEM.

Q.10-11 In the latest model, how many cellulose chains do one cellulose microfibril have?

Section 1. Basic 5 terms: “cellulose”, “cellulose fiber”, “pulp fiber”, “wood cells”, and “cellulose microfibril”

Let’s start basic five terms of “cellulose”, “cellulose fiber”, “pulp fiber”, “wood cells/ wood cell walls”, “cellulose microfibril”. Even though their popularity, their definitions or meanings are not so clear, and often depend on the researchers background. Therefore, you must use these terms depending on the situation/audience, based on the deeply understandings.

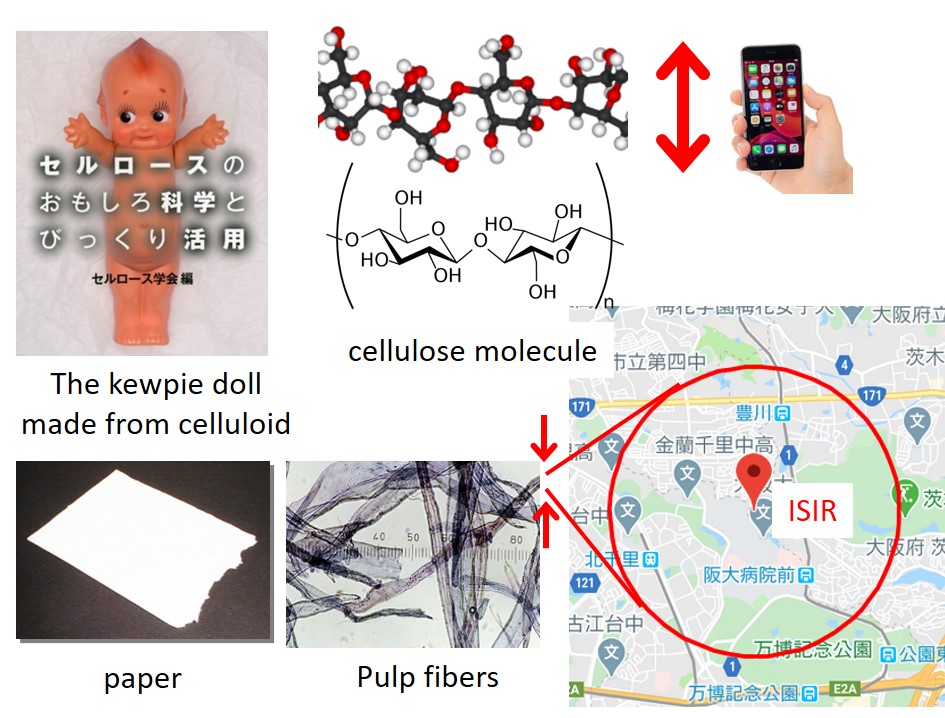

“Cellulose”

From “Encyclopaedia Britannica”, Cellulose is, a complex carbohydrate, or polysaccharide, consisting of 3,000 or more glucose units. The basic structural component of plant cell walls, cellulose comprises about 33 percent of all vegetable matter (90 percent of cotton and 50 percent of wood are cellulose) and is the most abundant of all naturally occurring organic compounds. Nondigestible by man, cellulose is a food for herbivorous animals (e.g., cows, horses) because they retain it long enough for digestion by microorganisms present in the alimentary tract; protozoans in the gut of insects such as termites also digest cellulose. Of great economic importance, cellulose is processed to produce papers and fibres and is chemically modified to yield substances used in the manufacture of such items as plastics, photographic films, and rayon. Other cellulose derivatives are used as adhesives, explosives, thickening agents for foods, and in moisture-proof coatings.

Do you understand it?? lol

From my idea, the term of “cellulose” is often appeared in the chemistry field, and used with the same meaning of “cellulose molecule”. “Cellulose molecule” is a linear polymer of glucose units. The cellulose molecules are obtained by dissolving of high purity of cellulose fibers such as cotton.

Of course, however, the cellulose microfibrils are also one of the “cellulose”. Therefore, you must use the “cellulose molecule” not “cellulose” when you discuss the molecular level, and you must use the “cellulose microfibrils” not “cellulose” when you discuss the nano level.

“Cellulose fiber”

“Cellulose fiber” never be used in your literature, since there are many meanings in various field.

In the textile, “cellulose fiber” is one of the artificial fibers such as viscose, rayon, cellulose acetate. They are made by chemical dissolving of cellulose (mainly cotton), and their width is micron-millimeter level.

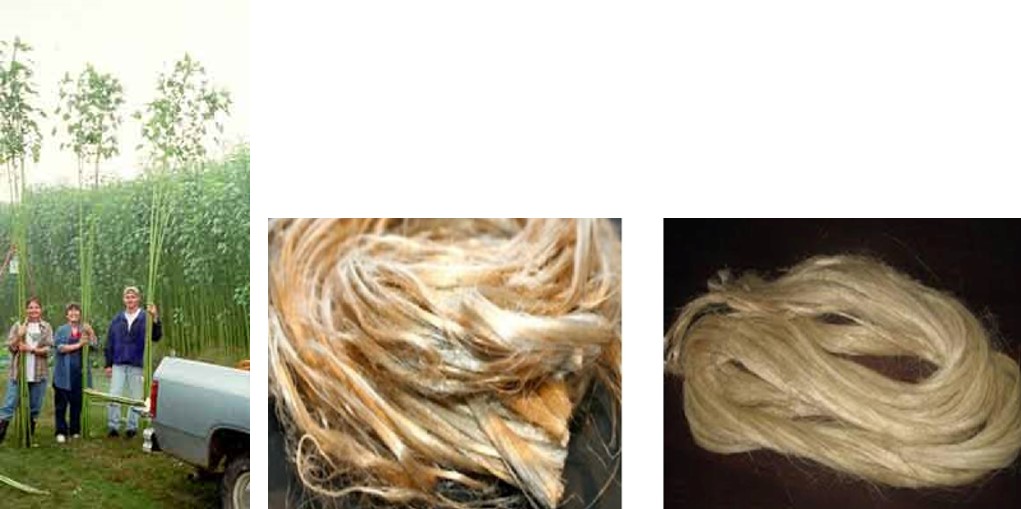

In the materials or composites, “cellulose fiber” is the natural fibers obtained from plants. For example, cotton, hemp, ramie, and kenaf. Their width is 10-50 um (maybe). Except for the cotton, these natural cellulose fibers also contain hemicellulose and lignin. WOW !! Cellulose fibers contain other chemical components…

Of course, the cellulose microfibrils are also one of the cellulose fibers.

In conclusion, you never use the term of “cellulose fibers” due to their wide applications and their famous.

“Pulp fiber”

“Pulp fiber” is made by the purification of wood chips, and is almost the same with the “wood cell”. The softwood pulps are 32-43 um wide and 2.7-3.6 mm long, and the hardwood pulps are 20-25 um wide and 0.7-1.6 mm long (ref 1). However, from the dictionary, “pulp” is “a soft wet substance that is made especially by pressing hard on something” or “the soft, juicy, edible part of a fruit”. Therefore, our meaning is not acceptable for all the people (It is just a jargon in our field) . You must carefully select the terms, which is the best for the reader or audience, not for you or your supervisors.

ref 1. p 412 in「セルロースの事典」 There are various reports about softwood & hardwood pulp. In common, hardwood pulps are shorter than softwood pulps among all the information.

“Wood cell/ wood cell walls”

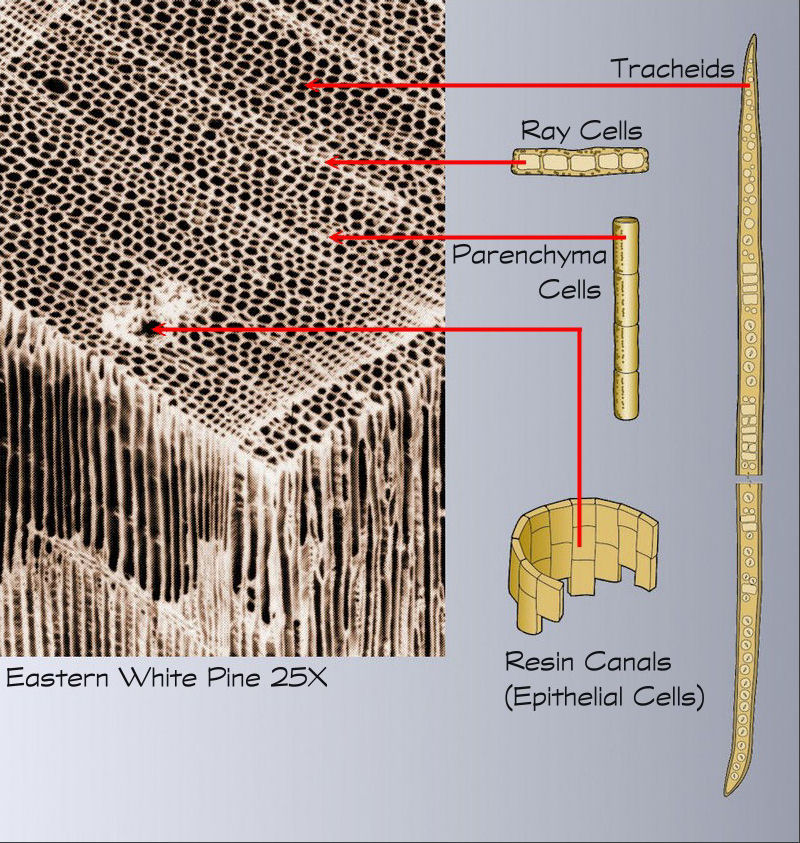

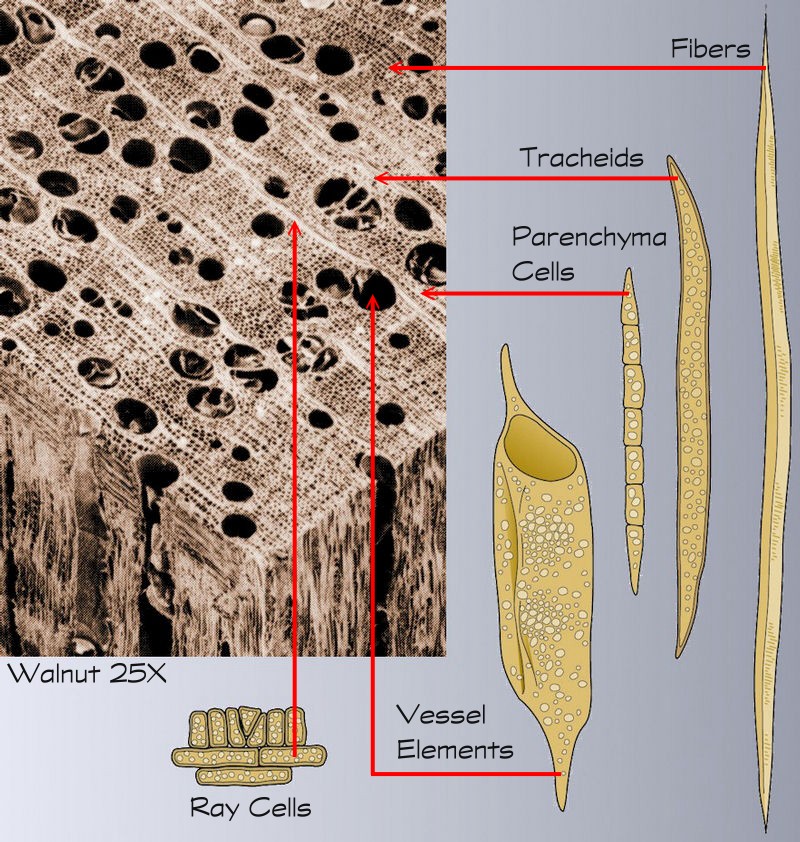

“Wood cells” generally indicates the tracheid (in softwood) and fiber (木部繊維 in hardwood). This “fiber (木部繊維)” is a special term in the wood structure (see the below picture in hardwood). “Tracheid in softwood” & “fiber in hardwood” are presented by Cote’s model.

If you would like to get a phD, let’s learn more about the types of wood cell walls.

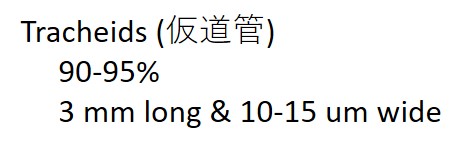

In softwood, the cells consist of tracheids (仮道管), ray cells (放射細胞), parenchyma cells (柔細胞), and resin canals (樹脂道). Among them, the tracheid is the main components (90-95%). Tracheid in Japanese ceder (Sugi) is around 3 mm long and 10-15 um wide (木材の構造, p29).

http://workshopcompanion.com/KnowHow/Wood/Hardwoods_&_Softwoods/1_Wood_Botany/1_Wood_Botany.htm

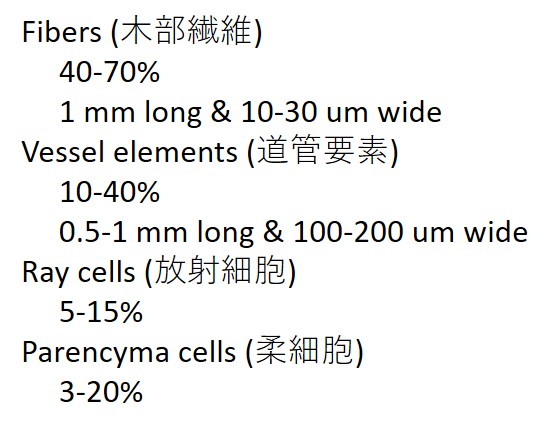

Hardwood is more complicated. In hardwood, the wood cells consist of fibers (木部繊維), tracheids (仮道管), vessel elements (道管要素), ray cells (放射細胞), and parenchyma cells (柔細胞). Their ratios are different in wood species; fibers (木部繊維) are 40-70%, vessel elements (道管要素) are 10-40%, ray cells (放射細胞) are 5-15%, and parenchyma cells (柔細胞) are 3-20%. The fibers (木部繊維) is around 1mm long and 10-30 um, and the vessel elements (道管要素) is 0.5-1 mm long and 100-200 um wide (木材の構造, p29). Don’t forget there are many kinds of wood cells in hardwood, when you use the hardwood as the sample.

http://workshopcompanion.com/KnowHow/Wood/Hardwoods_&_Softwoods/1_Wood_Botany/1_Wood_Botany.htm

“Cellulose microfibril”

“Cellulose microfibril” is the framework of the plant cell, and its width is 2-5 nm, consisting of 18 cellulose chains. Ten to twenty cellulose microfibrils are formed in the cell walls as the bundle of cellulose mirofibrils. Although we sometimes meet “elementary microfibril” in the literature, the term has already be denied (The researchers who have not enough knowledge love this term.)

In general, “cellulose nanofiber” must mean “cellulose microfibril”. However, most researchers call their own sample, which are much larger than the cellulose microfibril (often micro-sized samples), as “cellulose nanofibers”. Therefore, everyone confuse what is cellulose nanofiber…

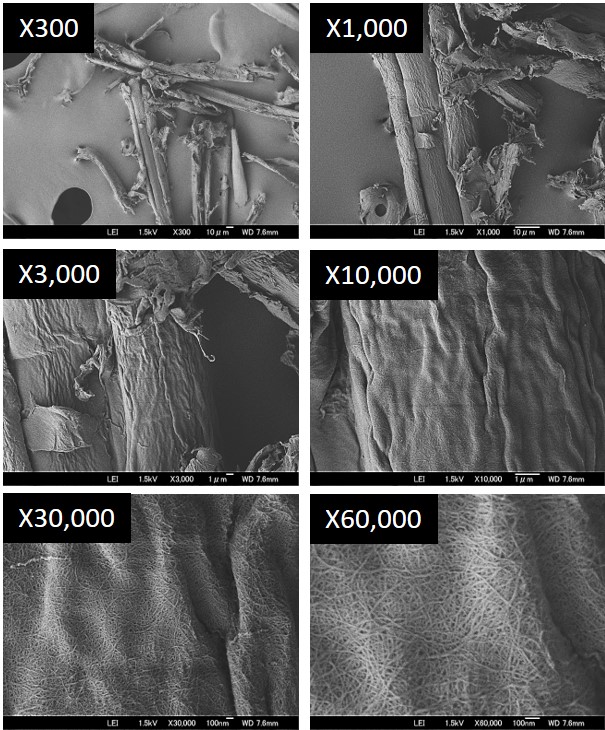

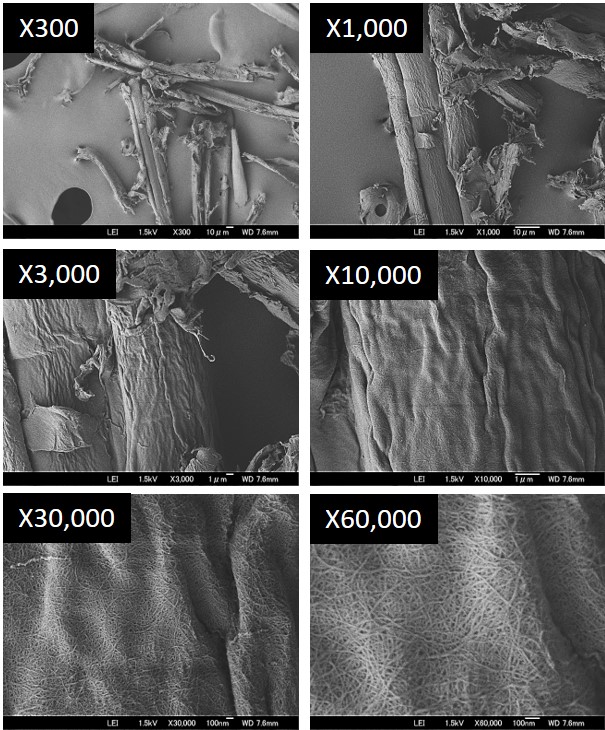

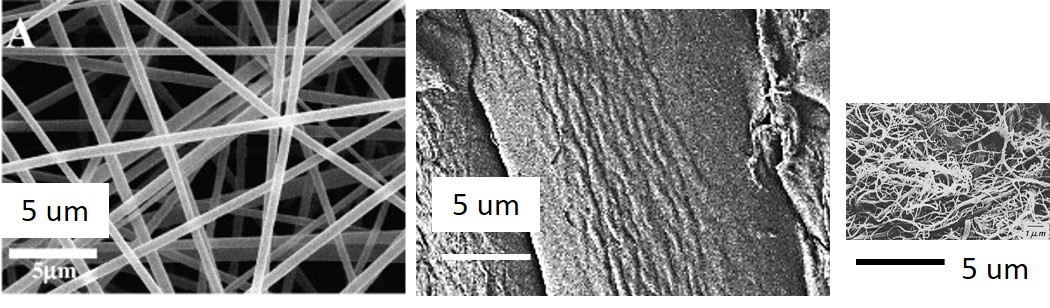

Why the mistakes occur? It often comes from high magnification microscopic observations. Let’s see these pictures. The observation objects are micro-sized pulps. When we observed it at lower magnification less than 1,000 times, we can find the micro-sized fibers. However, when the magnification is over 10,000 times, we find only the bundles of cellulose microfibrils on the cell walls, never seen the micro-sized fibers. Namely, any cellulose fibers could be seen as the nanofibers at over 10,000 times magnification.

We have two simple ways to confirm the cellulose nanofibers or not. First one is that the dispersion less than 1wt% concentration is clear transparent or white (opaque). Second one is that the dried film of the dispersion is clear transparent or white (opaque). If the both are white (opaque), it is not the cellulose nanofiber sample. (It may be the microfibrillated cellulose.) If the both are transparent clear transparent, it is the cellulose nanofiber sample. (Be careful, there is a possible that your sample is the water soluble cellulose such as carboxymethyl cellulose).

Q 1-1. What is “cellulose”? Answer your opinion or impressive sentences.

Q 1-2. What is “cellulose molecule”?

Q 1-3. What is “cellulose fiber”?

Q 1-4. What is “pulp fiber”?

Q 1-5. How much size of softwood pulp and hardwood pulp?

Q 1-6. In the dictionary, what does it mean “pulp”?

Q 1-7. What is “wood cells”?

Q 1-8. Answer the main cells in the softwood, and its size & occupancy.

Q 1-9. Answer TWO main cells in the hardwood, and its size & occupancy.

Q 1-10. What is “cellulose microfibril”?

Q 1-11. Is there “elementary fibrils”?

Q 1-12. How much is the magnification suitable to truly recognize the micro-sized fiber as the micro-sized fibers using the microscopy?

Q 1-13. What kind of elements/materials in the clear transparent dispersion or film? Answer the two possibility?

Experimental Section : Seeing is believing !

You don’t need to do before you come to our group. Please do when you come to our university.

Ex 1-1. Take 3 wood surface pictures using softwood blocks, sliding microtome, and Keyenc microscopy.

This video tell you how to operate the sliding microtome.

https://youtu.be/alY84ZMmtbk

Ex 1-2. Using the softwood pictures, please find more than 3 cell types (for example, ray, parenchyma, tracheid, and resin canals)

Ex 1-3. Take 3 wood surface pictures using hardwood blocks, sliding microtome, and Keyenc microscopy.

Ex 1-4. Using the hardwood pictures, please find more than 4 cell types (for example, fibers, tracheids, parenchyma, vessel, and ray)

Ex 1-5. Take pictures from pulp fibers to the CMF on the cell walls, using the FE-SEM. Pulp fibers by Wise or PA method are suitable (Kraft or Sulfite pulps are acceptable, but they may be hard for the observation). Pulp fibers should be dried from the ethanol series.

You can learn the procedures of “the ethanol series” and “FE-SEM preparation & operation” from the videos in the below.

http://www.nogimasaya.com/favorite/experiment-video/

Ex 1-6. Using the FE-SEM pictures, please tell the width of CMF on the cell walls. Please show me the process, not only the value. Namely, describe how to determine the width.

For example, the pictures are inserted into the ppt file, the object width are measured using the line. The line length is converted to the object length, based on the scale bar.

Section 2. Figure out the size gap

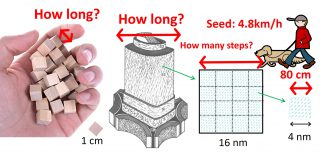

In this section, please image “your one step (80cm)” is the same size with the cellulose microfibril width. For simply thinking, the cellulose microfibril consist of 36 (6×6) cellulose chains, the width of cellulose microfibril sets 4nm, the width of their bundles sets 16nm, and the width of wood cells sets 16um (16,000 nm). Your walking speed sets to be 4.8km/hour.

Q 2-1. How long is the width of cellulose chain in this world? Which is larger between the width in this world & the length of your smart phone in the real world?

Q 2-2. How many steps in the cellulose microfibril bundles?

Q 2-3. How long is the wood cells in this world? How long time do you need for a walk?

Q 2-4. Draw a circle on a map, and send me the captured picture. before you send a picture file, please check this site.

http://www.nogimasaya.com/favorite/reduce/

The center is located on the ISIR, and the diameter is the answer of Q 2-3. Please use the below website. Other service is no problem.

http://yagijijii.com/google/concentriccirclemap.htm

https://maps.multisoup.co.jp/blog/1666/

Q 2-5. How long is 1 cm wide wood block in this world? How long days do you need to take a walk?

Q 2-6. As you know, the lake Biwa is the largest lake in Japan. Its one loop is around 240 km. How long days do you need to take a walk around the lake in the real world?

Q 2-7. Play back these questions.

In this world, a cellulose molecule, how much is the length and what is the same length with it?

In this world, a cellulose microfibril, how much is the length and what is the same length with it?

In this world, a wood cell (pulp fiber), how much is the length and what is the same length with it?

Intermission 1. What is “Nanocellulose”?

In this field, there are many similar terms, such as “nanocellulose”, “cellulose nanofiber”, “cellulose microfibrils”, “microfibrillated cellulose”, “cellulose nanocrystal”, “cellulose microcrystalline”. Moreover, as more simple terms, “cellulose”, “cellulose molecular”, “plant fibers”, “pulp fibers” and so on. Can you explain the all? Don’t mind, if you cannot. Most researcher also cannot explain them, I think. However, you have to understand them for your brilliant research life in the future, since they are the first barrier for the newcomers.

Here, we have a very brief introduction about “nanocellulose” and “cellulose nanofibers & its resources”.

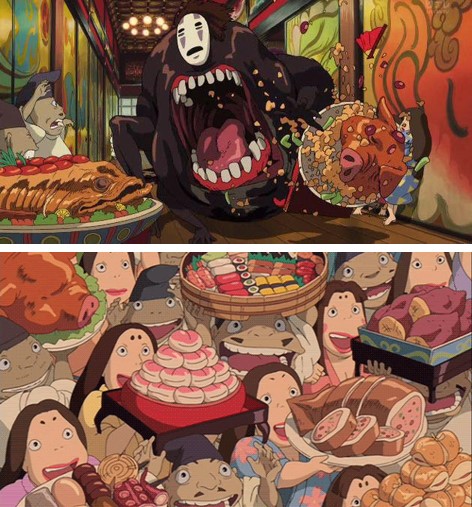

Let’s start what is the “nanocellulose”? I cannot explain it because there are the original images/concepts in each researchers. I think “nanocellulose” is one of the evil spirits in the human society. It looks like “Kaonashi (No-face)” in “Spirited Away (千と千尋の神隠し)” by Hayao Miyazaki’s movie. Let’s see this scene. Many people gathered it to get the wealth !! Do you know what happened after that?

“Cellulose microfibril” is able to be explained, because there is a scientific definition.

“Cellulose microfibril” is a basic element in all the plant cell walls. For its starting materials, there are many kinds of plants of cotton (綿花), bagasse (バガス, crushed sugar cane or beet refuse from sugar making), hemp (ヘンプ・麻・大麻), kenaf (ケナフ), ramie (ラミー) and so on. Among them, since the wood is the major cellulose source, the cellulose microfibrils from wood are mainly researched. Therefore, here we mainly introduce the wood cellulose microfibrils and their production processes.

In1-1. Which is “cotton”, “bagasse”, hemp”, kenaf” and “ramie”? Please answer

a)

b)

c)

d)

e)

Section 3. Paper history: why the wood cellulose is important?

There are many cellulose resources on the earth. Among them, wood cellulose is the most important. Here you will understand the reason from the paper history.

Cellulose is famous as the raw-materials in paper. The paper was invented by Chinese eunuch of Cai Lun (蔡倫) at around A.C. 100. At that time, the paper was made from the plant fibers such as hemp. And then, the paper making technology was transmitted into Europe in the 12th century. In the Europe, the paper was made from the old rags because the plant fibers were rare materials in Europe. As you image, the old rags are not so rich for the raw materials. However, the old rags could fully supply for the paper materials, because the book or writing documents users were only limited in the noble class. The easy mode was ended by Gutenberg at around 1450. His invention of the printing press (活版印刷) was able to mass produce the book or writing documents for ordinary people, and then the shortage of old rags had become a big issue. Four hundreds years passed, a French chemist of Anselme Payen(アンセン・ペイエン)discovered white fibrous materials from the wood, which was named “cellulose”, in 1838. This is the invention of cellulose. But it is only in 1926 that the structure of cellulose was clearly established by Staudinger (シュタウディンガー、”the father of polymer chemistry”), who demonstrated the existence of macromolecules, which he characterized as polymers.

Cai Lun (蔡倫)

Gutenberg and printing press (活版印刷)

Anselme payen (アンセン・ペイエン) and his award medal

Hermann Staudinger (Nobel prize winner 1953)

From it, human beings could produce the cellulose from the wood. In 1840, Germany developed the “groundwood pulps” (砕木パルプ、さいぼく) by subjecting wood to an abrading action. And then, U.S.A. developed the “sulfite pulps” in 1867, and Germany developed the “kraft pulps” in 1879. Sulfite process, sulfite also spelled Sulphite, is a chemical process for the manufacture of paper pulp that employs an acid bisulfite solution to soften the wood material by removing the lignin from the cellulose. Kraft process, (from German kraft, “strong”), is a chemical method for the production of wood pulp that employs a solution of caustic soda and sodium sulfide as the liquor in which the pulpwood is cooked in order to loosen the fibers. Because I don’t know them well, if you need more information, please ask “Encyclopedia Britannica (https://www.britannica.com/).

Since these developments that cellulose/cellulose fibers produced from the wood, the paper is able to be the important/major items in our society. Even now, if they are only from old rags or plant fibers, paper should be still minor or limited items only for the noble class. These episodes give us a good lesson that we must select the starting material depending on the consumption volume. Don’t you target the high volume market using the specialized/minor starting materials?

Q 3-1. What is raw materials when the paper was invented?

Q 3-2. What is the technology that drastically increased paper consumption in the 15th century?

Q 3-3. At that time, what is the paper raw materials?

Q 3-4. Who and when discovered the cellulose from the wood?

Q 3-5. Who and when clearly established cellulose chemical structure?

Q 3-6. Please answer three typical pulping names and its processes.

Section 4. How to produce the paper in the factory

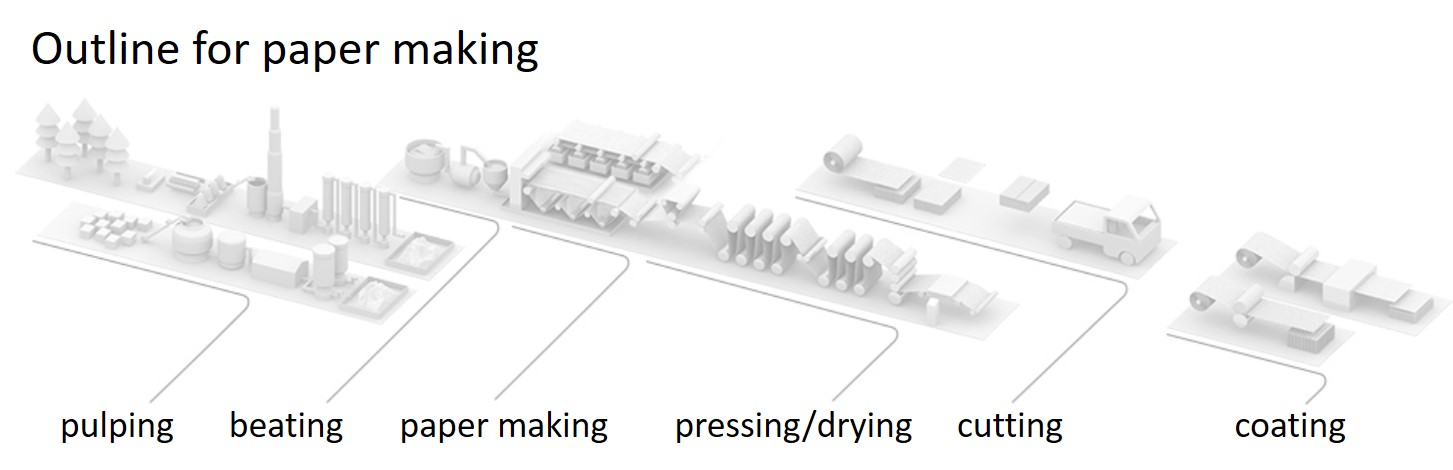

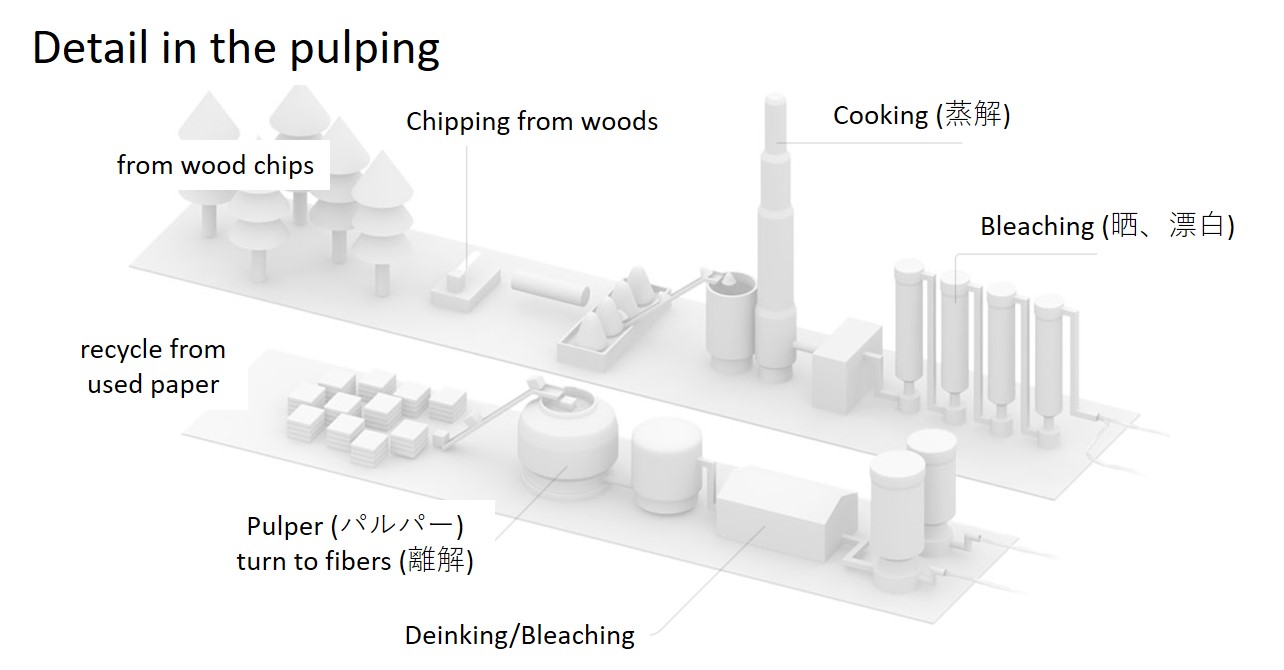

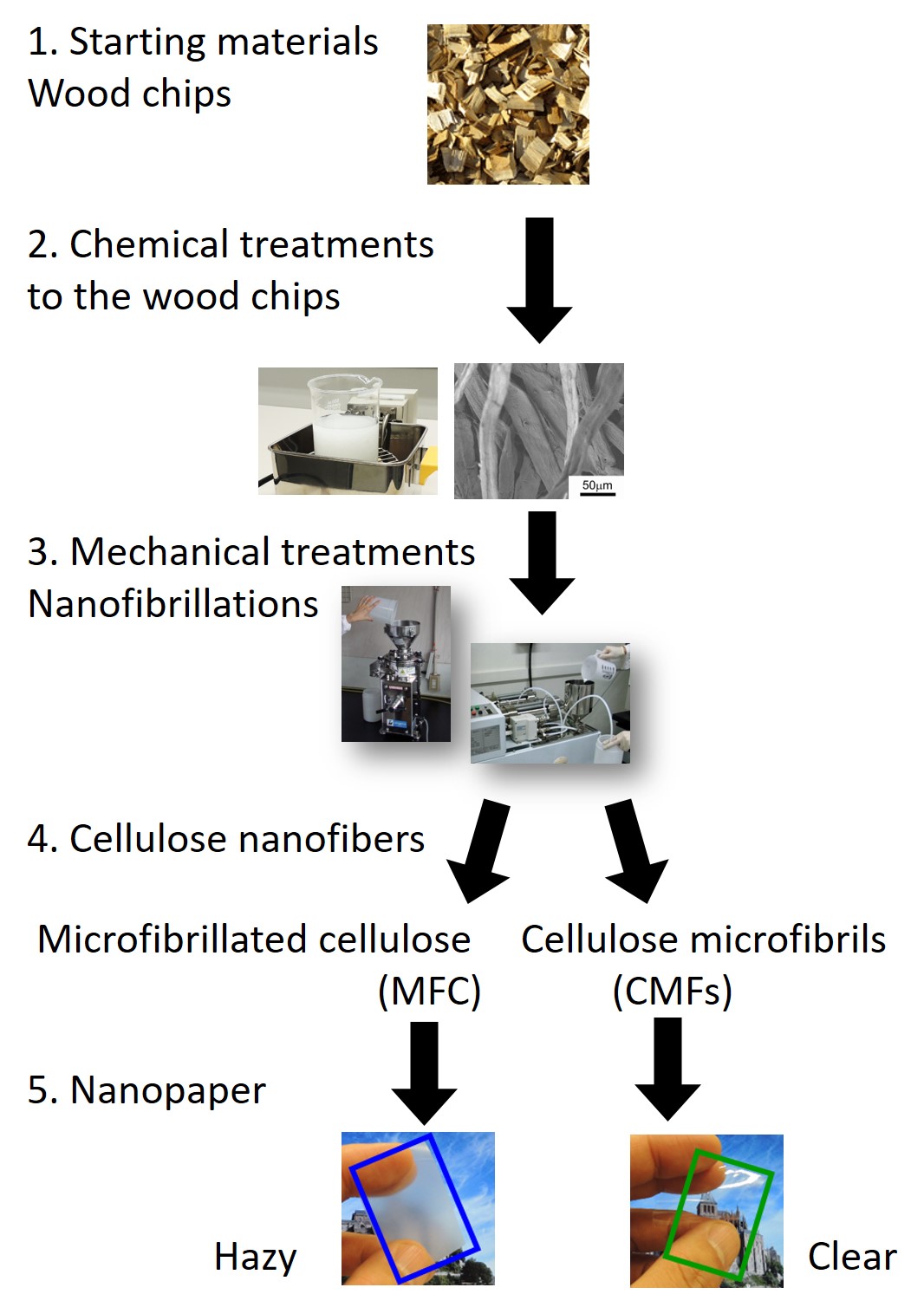

Simply speaking, the process consist of chemical pulping, mechanical beating, and suspension drying. Their procedures are almost the same with the cellulose nanofiber & nanopaper procedures.

In the paper, starting from the wood chips, the chips are treated by chemical treatments, and then rough fibrilation of mechanical beating, and finally drying of pulp fiber suspensions.

In the nanopaper, starting from the wood chips, the chips are treated by chemical treatments, and then hard mechanical fibrilations, and finally drying of nanofiber suspensions.

Actually, there are some minor differences. For example, in chemical treatments, some traditional pulping conditions are not suitable for the cellulose nanofibers. In mechanical & drying treatment, cellulose nanofiber & nanopaper need much stronger or longer conditions than the traditional pulp & paper. However, their outline are almost the same.

I find the very good & beautiful website about the “how to produce the paper”. Let’s access & understad it.

竹尾 (TAKEO Co., Ltd.)

https://www.takeo.co.jp/finder/papermaking/

Unfortunately, this is the Japanese only. So translate in English here.

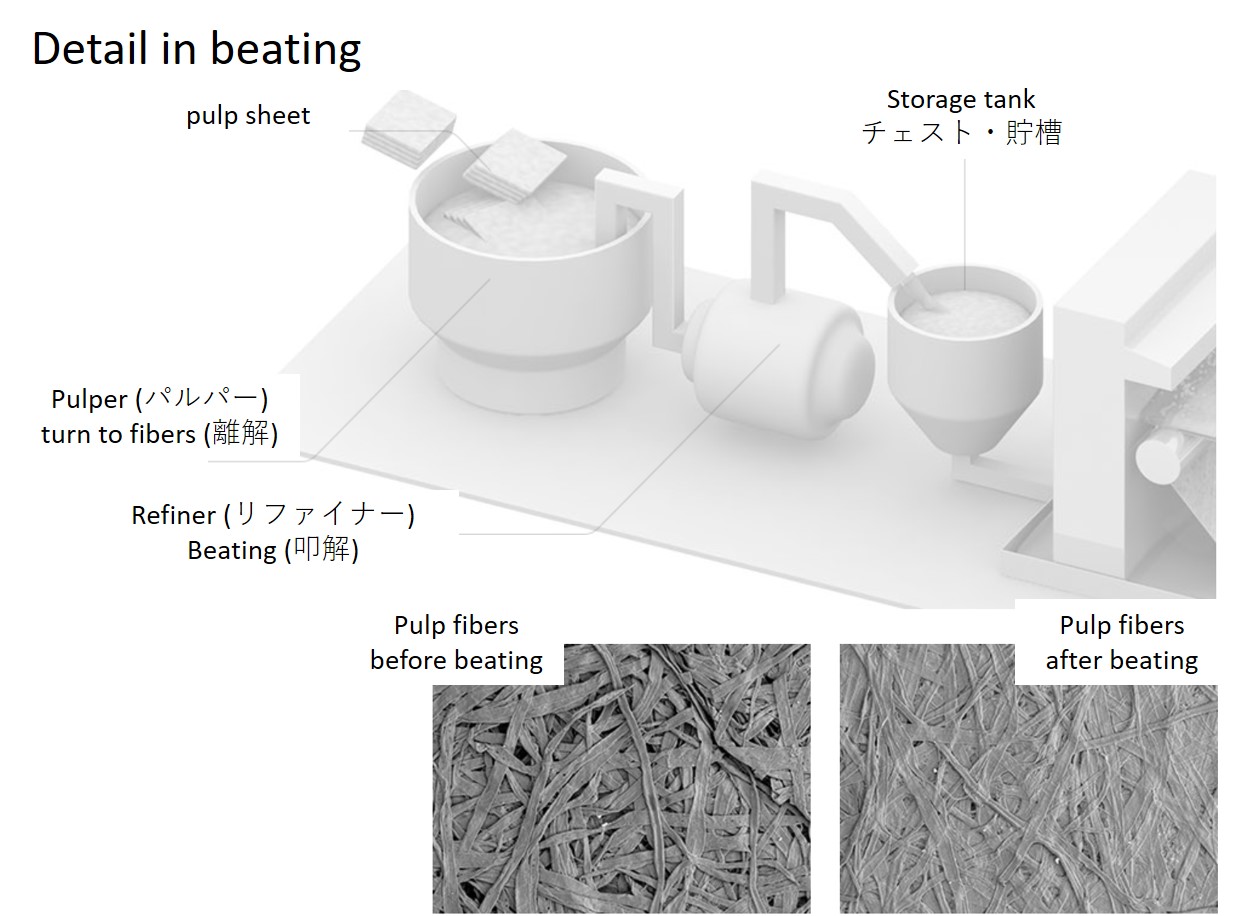

This is the outline illustration. There are many processes in the paper making. The pulping (パルプ化) produces the pulp fibers from wood chips or used paper (古紙). The beating (離解・叩離) makes the pulp fibers fine ones, which is called “fibrillation (フィブリル化)”. Third process is called paper-making (抄紙) or wire-part (ワイヤーパート), which produce the wet sheet from the pulp fiber suspension. In the next process, the wet sheet is pressed and dried. This process also include the adding of the sizing agent (サイズ剤) and calendar press (カレンダー処理) to improve the flatness or increase the density. In the last cutting process, the raw paper cut into the commercial size and then are packaged. To produce the specialized paper, the coating process often is applied. In the coating process, the paper is embossed to create some patterns or coated/laminated for the decoration. From here, we focus on the early two stages of “pulping” and “beating”.

Paper made from wood chips or used/recycled paper. Starting from the wood chips, the wood chips are cooked by some chemicals to make pulp fibers under the cooking and bleaching process. Softwood produces the higher strength paper due to the long pulp fibers (cell walls), and hard wood produces good texture paper due to the short pulp fibers (cell walls). Used paper is also the main resources to produce the paper. In Japan at 2019, the paper materials are 65% in the used paper and 35% in the wood chips. Namely, the used/recycled paper is the major starting materials for the pulp & paper industry.

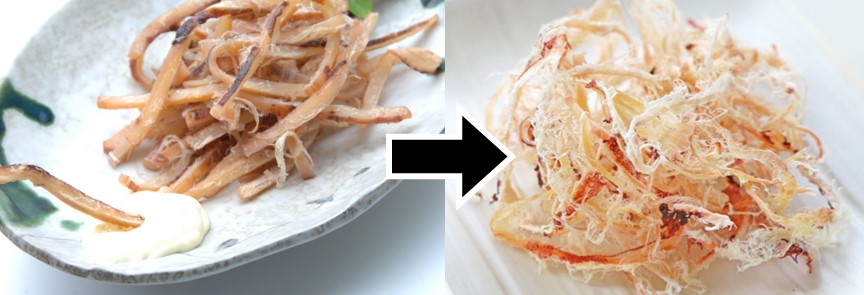

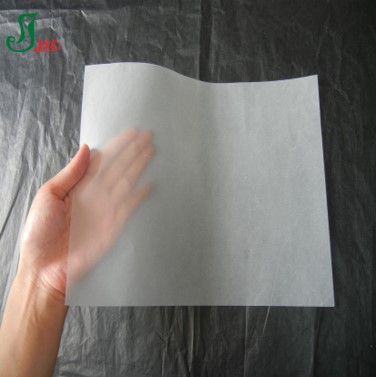

This beating process (叩解 こうかい) is called fibrillation (フィブリル化). In general, the fibrillation is done by refiner machine. After the beating/fibrillation, the pulp fibers makes not only fine but also 毛羽立ち. Sorry, I can not find the good English for 毛羽立ち. So, please see the below picture, which explain “毛羽立ち” by the “fibrillation”. The fibrillated pulp improve the paper strength and increase the paper density due to the entanglements with other fibers. The strong beating or much fibrillation makes the paper to the “tracing paper”. Someone may find that the beating/fibrillation brings very similar enhancement with the nano-fibrillations.. Yes, it is very similar, but the nanofibrillation is more powerful than the beating due to the drastic size change.

When you see the two pictures before/after beating, you will find the fibrillated paper become dense. As you can image easily, the fibrillated paper (more dense paper) become translucent from the opaque (white). We call it “tracing paper”.

This is an image of “毛羽立ち” by the “fibrillation”. Therefore, the fibrillation produces not only “thinner fiber width” but also “fiber branches or networks”.

Q 4-1. Simply answer how to produce the paper.

Q 4-2. Answer how to produce the cellulose nanofiber & nanopaper?

Q 4-3. What kind of paper was produced from softwood and hardwood, respectively? Answer the reasons, too.

Q 4-4. What is the major source for the paper in Japan? How much percentage?

Q 4-5. The beating process, what does it called? and what is used?

Q 4-6. What is improved and increased by the fibrillated pulps?

Q 4-7. What kind of paper using the strong beaten/fibrillated pulps?

Section 5. History of tracing paper

You know about the tracing paper? So, it is not opaque/ white paper, but their clearness is not so high. There are three methods to prepare the tracing paper as below, which are very similar with transparent cellulose nanofiber composites, cellulosic plastics, and nanopaper.

1. Impregnating the paper with a substance that has the same or nearly the same reflection index as cellulose. (Namely, mixed with other materials of plastics or wax. similar with transparent cellulose nanofiber composites)

2. Immersing the paper in acid which causes the fibers to swell and reduce the air pockets. (Namely, the paper is dissolved. similar with transparent cellulosic plastics)

3. By mechanically OVER beating the pulp, sometimes in combination with a finishing calendering. (Namely, densely packed and smooth surface. similar with the transparent nanopaper)

A tracing paper, whose appearance is almost the same with the translucent nanopaper. So, it may be reasonable that the translucent nanopaper is one of the tracing paper… What is the difference?

A tracing paper, whose appearance is almost the same with the translucent nanopaper. So, it may be reasonable that the translucent nanopaper is one of the tracing paper… What is the difference?

Since there is a long long history about the tracing paper, Leonardo da Vinci (1452-1519), who is the Italian superman in the Renaissance, also used it. Since the paper from wood pulps was not net invented in his period, he used the tracing paper from the parchment (羊皮紙) or old rags, which were prepared with 1 or 2. Among three methods, No.3 is the most interesting for the paper from wood pulp fibers. The tracing paper from wood pulps was born at the end of the 19th century. When a pulp accidentally got stuck too long in the beater, the prolonged beating resulted in a transparent paper named pergamyn (ref.1, 2). Today such papers are also called natural tracing paper, imitation parchment or glassine (グラシン紙).

a map on tracing paper around 1820’s (paper type/source not specified)

a map on tracing paper around 1820’s (paper type/source not specified)

from https://cool.culturalheritage.org/coolaic/sg/bpg/annual/v16/bp16-09.html

In summary, the opaque/white paper from wood/ wood pulp fibers were born in the 19th century, and the translucent tracing paper was also born in the the 19th century by the “over” fibrillation.

ref. 1, H. Homburger and B. Korbel, Architectural Drawings on Transparent Paper: Modifications of Conservation Treatments. AIC The Book and Paper Group Annual, 1999. 18: p. 25-34.

ref. 2. K. M. Axelsson Transparent papers: A review of the history and manufacturing processes, PAPER HISTORY 20 (2016) 21-31

Q 5-1. Paper from wood, when was it born?

Q 5-2. Tracing paper from wood, when was it born?

Q 5-3. Tracing paper from wood, how to be born?

Intermission 2. The easiest way to get cellulose nanofibers

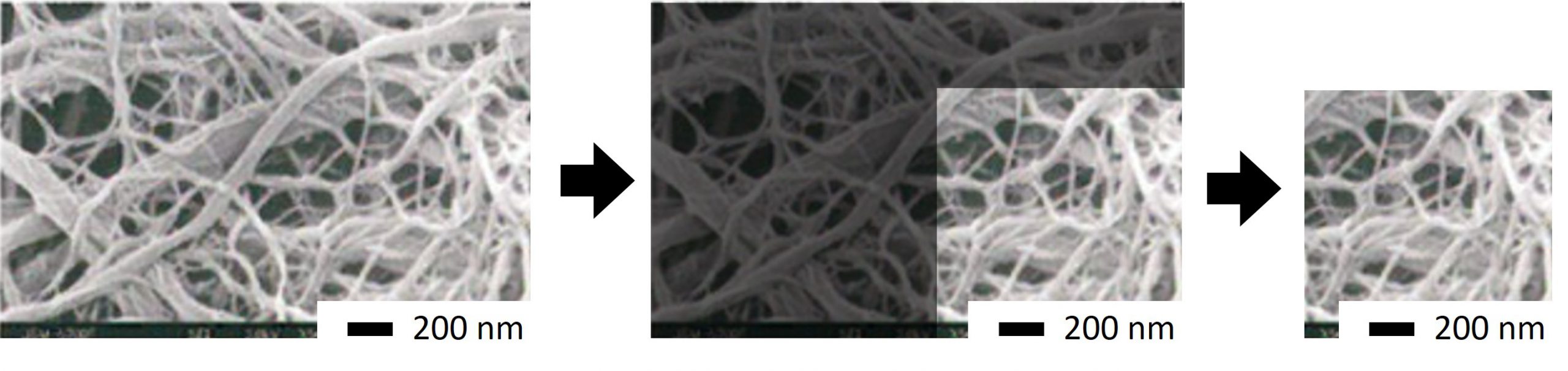

The below pictures present the easy way to obtain cellulose nanofibers. I know that you have never done such manners in your PC. How about the SEM observation? At the SEM observation, everyone unconsciously focus on what you want (cut or trim what you don’t want)…

Don’t forget the below pictures, too. When you have enough SEM skill, you will observe the cellulose microfibrils on the pulp fibers.

As a conclusion, don’t believe the SEM pictures & don’t judge from the SEM picture about the nanofibers. You must capture at least two magnification “less than 5,000 times” and “over 10,000 times”, when you discuss the cellulose nanofibers. If one picture is over 10,000 times only, we don’t know your samples are pulp fibers or cellulose nanofibers..

Q In-2. How much magnification must you capture to discuss the cellulose nanofibers?

Section 6. How to make the cellulose nanofiber & nanopaper

Here, I will briefly explain how to make the cellulose nanofiber & nanopaper. All the cellulose nanofibers are produced from the wood chips. Wood chips are chemically treated, and then mechanically nanofibrillations. All the cellulose nanofibers need the both process. Obtained cellulose nanofibers consist of two groups of “microfibrillated cellulose” and “cellulose microfibrils”. “Cellulose microfibrils” can produce the transparent nanopaper, but “microfibrillated cellulose” produce only the hazy nanopaper. What is “microfibrillated cellulose”? I will deeply explain it in the other chapter. In my idea, the microfibrillated cellulose are not cellulose nanofibers, due to their history & definition, and since moreover they contain much micro-sized fibers. You can easily understand what is the cellulose nanofiber, when you will distinguish “microfibrillated cellulose” and “cellulose microfibrils”.

Someone proposed “chemical nanofibers” or “mechanical nanofibers”. However, all the cellulose nanofibers need the both processes in chemical & mechanical treatments since cellulose nanofibers are produced/started from the wood chips. If only the chemical process, the wood chips become just “pulp”. If only the mechanical process, the samples also contain lignin. Therefore, the definition of “chemical or mechanical nanofibers” are wrong.

Among the both processes, chemical treatment is more important than mechanical ones. All mechanical processes/machines can produce the same quality nanofibers. The nanofiber quality only depend on the chemical process or pulp types. For example, when you use the TEMPO, Wise, or peracetic acid pulps, you will obtain the cellulose microfibrils (CMFs). When you use the kraft or sulfite pulps, you will obtain the microfibrillated cellulose (MFC). Namely, you must use the TEMPO, Wise, or peracetic acid pulps to produce the transparent nanopaper, and you can use kraft or sulfite pulps to produce the hazy nanopaper.

Q 6-1. What is the starting materials in the cellulose nanofibers?

Q 6-2. What kind of processes do you need to produce the cellulose nanofibers?

Q 6-3. Among the both processes, which is more important?

Q 6-4. The definition of “chemical nanofibers” or “mechanical nanofibers” are wrong. Please explain the reason.

Q 6-5. Please answer the two types of cellulose nanofibers, not “chemical or mechanical” nanofibers.

Q 6-6. Please explain the nanopaper appearances in the two cellulose nanofibers.

Q 6-7. What kind of pulp should you use to obtain the cellulose microfibrils (CMFs)?

Q 6-8. What kind of pulp should you use to obtain the microfibrillated cellulose (MFC)?

Intermission 3. Bottom up approach to the cellulose nanofibers

The micron-sized materials (pulp fiber) and angstrom-sized materials (cellulose molecules) have already created in the 19th century. However, we needed more time to create the middle size materials of cellulose nanofibers.

In the 19th century, the celluloid was created by cellulose polymer (upper), and the paper was created by wood pulp fibers (lower).

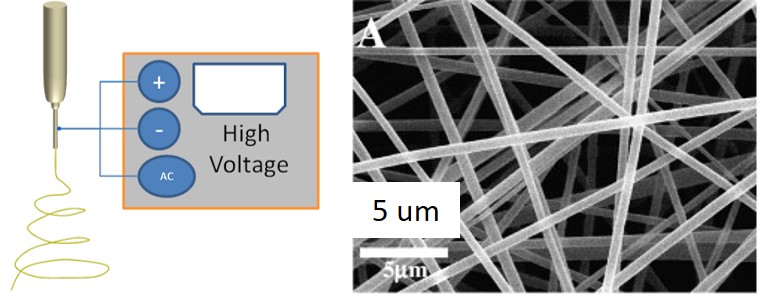

There are two ways for the cellulose nanofibers, which is the “bottom up” from the cellulose molecules, or the “top down” from the wood cells (pulp fibers). The bottom up approach was achieved in the 21st century by the electrospinning of the cellulose molecules such as cellulose acetate. However, compared with the electrospun nanofibers produced from other polymers, the electrospun cellulose nanofibers do not have exclusive properties.

The diagram of the electro-spinning, and one of the examples of cellulose acetate electrospun nanofibers (Tang 2008).

Since the cellulose molecule is a linear polymer, the cellulosic polymer have relatively higher mechanical properties than other polymers, not all the materials (Most polymer consist of entangle chains, not so high crystallinity). In contrast, the native cellulose microfibrils consisting of linear chains have high crystallinity. Therefore, the cellulose microfibrils have outstanding properties among all the materials. Simply, the cellulosic polymer has higher propertied than common polymers because of the linear chains, and the cellulose microfibrils have higher properties than common materials because of linear chains & high crystallinity.

Let’s back to the electrospun cellulose nanofibers. The electrospun cellulose ones are made from the cellulose molecules, not the cellulose microfibrils. Their starting materials still kept relatively higher mechanical properties than other polymers, due to the linear chains. However, the starting cellulose molecules have already lost the high crystallinity in the native cellulose microfibrils. As a result, the electrospun cellulose nanofibers do not have exclusive properties.

Moreover, the electrospun nanofibers (several hundreds nano-meter wide) are much wider than the cellulose microfibrils. As shown in the below pictures, when the cell walls are observed at the same magnification, the cellulose microfibrils cannot be found due to their thin width. Several hundreds nm width cellulose fibers had already reported in 1983 by Turbak, which are called as the “microfibrillated cellulose” (MFC, ミクロフィブリル化セルロース), not “cellulose nanofibers. The cellulose nanofiber show the transparent appearance in the water dispersion or the dried film. However, these wider fibers of the eletrospun ones and the microfibrillated cellulose show the white or translucent under the dispersion and dried film. In conclusion, there are no reports from the bottom up approach that the thin cellulose nanofiber as much as the cellulose microfibrils at the present.

Electrospun cellulose acetate nanofibers (left), the cellulose microfibrils in the cell walls (center), and the microfibrillated cellulose (right) under the same magnifications.

In the conclusion, the native cellulose microfibrils have high mechanical properties due to the linear chain & high crystalinity. When the cellulose/cellulose microfibrils are dissolved by some solvents, the cellulose polymers were obtained with losing high crystallinity. Since the electrospun cellulose nanofibers by the bottom up approach were made from the cellulose polymers, they don’t have outstanding properties among all the materials. Therefore, we must obtain the intact cellulose microfibrils as the cellulose nanofiber. Only the nano-level size can not bring the special properties.

In3-1. Answer the two ways to produce the cellulose nanofibers.

In3-2. Answer the bottom up approach to produce the cellulose nanofibers.

In3-3.Which is higher mechanical properties in the cellulosic and the common polymer? Also explain the reason.

In3-4. Which is higher mechanical properties in the cellulosic polymer and the cellulose microfibrils? Also explain the reason.

In3-5. Compared with the electrospun nanofibers produced from other polymers, the electrospun cellulose nanofibers do not have exclusive properties. Please explain the reason.

In3-6. How much the width in the bottom up approached nanofiber?

In3-7. Sort the Order the larger width to smaller one in the electrospun cellulose acetate nanofibers, the cellulose microfibrils, and the microfibrillated cellulose.

In3-8. Which is the transparent water dispersion among the electrospun cellulose acetate nanofibers, the cellulose microfibrils, and the microfibrillated cellulose?

Overview

Answer these questions.

Q 1-2. What is “cellulose molecule”?

Q 1-4. What is “pulp fiber”?

Q 1-7. What is “wood cells”?

Q 1-10. What is “cellulose microfibril”?

Q 1-11. Is there “elementary fibrils”?

Q 2-7. Play back these questions.

In this world, a cellulose molecule, how much is the length and what is the same length with it?

In this world, a cellulose microfibril, how much is the length and what is the same length with it?

In this world, a wood cell (pulp fiber), how much is the length and what is the same length with it?

Q 3-4. Who and when discovered the cellulose from the wood?

Q 3-5. Who and when clearly established cellulose chemical structure?

Q 4-1. Simply answer how to produce the paper.

Q 4-2. Answer how to produce the cellulose nanofiber & nanopaper?

Q 4-5. The beating process, what does it called? and what is used?

Q 4-6. What is improved and increased by the fibrillated pulps?

Q 4-7. What kind of paper using the strong beaten/fibrillated pulps?

Q 5-1. Paper from wood, when was it born?

Q 5-2. Tracing paper from wood, when was it born?

Q 5-3. Tracing paper from wood, how to be born?

Q 6-1. What is the starting materials in the cellulose nanofibers?

Q 6-2. What kind of processes do you need to produce the cellulose nanofibers?

Q 6-3. Among the both processes, which is more important?

Q 6-6. Please explain the nanopaper appearances in the two cellulose nanofibers.

Q 6-7. What kind of pulp should you use to obtain the cellulose microfibrils (CMFs)?

Q 6-8. What kind of pulp should you use to obtain the microfibrillated cellulose (MFC)?

In3-3.Which is higher mechanical properties in the cellulosic and the common polymer? Also explain the reason.

In3-4. Which is higher mechanical properties in the cellulosic polymer and the cellulose microfibrils? Also explain the reason.

In3-5. Compared with the electrospun nanofibers produced from other polymers, the electrospun cellulose nanofibers do not have exclusive properties. Please explain the reason.

© Department of Functionalized Natural Materials ISIR, Osaka University